Faster, Safer Field Dielectric Tests at Substantial Savings

The PCORE Test Terminal makes it possible to perform field dielectric tests of substation equipment such as transformers and circuit breakers faster, more safely, and at substantial savings. These are benefits that hundreds of utilities worldwide are already experiencing as they turn to the PCORE Test Terminal—and regular field dielectric tests—as a means of extending the service life of existing equipment

Eliminates Need to Physically Remove Power Bus

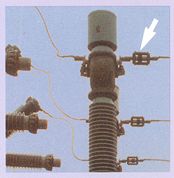

The PCORE Test Terminal functions as an electrical switch permanently connected in series between the power bus and the equipment to be tested, so it eliminates the need to physically remove the power bus during testing. In the closed position, the PCORE Test Terminal permits electrical power to be transferred from the power bus to the equipment. When you wish to test the equipment, you first de-energize the power bus. Then you back off the two captive bolts at the top of the PCORE Test Terminal and loosen the other bolts to let the terminal's copper blades swing out in an open position.

With the bus grounded, the equipment is now isolated from the power bus and you may perform standard Doble or other dielectric tests. During testing, the equipment is energized by the high voltage cable from the Doble test set, and the center casting of the terminal is connected to the test set's "guard" so any stray leakage current is bypassed and returned to the test set without being measured.

Loosening and tightening the bolts on the test terminal and connecting the terminal to the test set takes only a matter of minutes. What's more, depending on the equipment you're testing and its location, testing can often be accomplished without a boom or bucket truck, or extra personnel.

Extended Service Life, Significant Savings, and More

Extended service life without a risk of equipment failure

If you extend the service life of existing substation equipment without performing periodic field dielectric tests, you face the risk that the equipment will fail electrically, resulting in expensive downtime, lost revenue, and costly repair and replacement. On the other hand, if you perform periodic field dielectric tests to ensure that your equipment doesn't fail but you haven't installed PCORE Test Terminals, your testing costs can be significant. Because PCORE Test Terminals make it so easy to test the dielectric strength of your substation equipment, they let you extend the equipment's service life without these added risks and testing costs.

Significant savings

By eliminating the need to physically disconnect the equipment being tested from the power bus, PCORE Test Terminals significantly reduce labor costs and boom and bucket truck time. The text, table, and graph on the next page can help you determine the savings you can expect when you install PCORE Test Terminals at your utility.

Reduced risk of equipment damage during bus removal

Because the PCORE Test Terminal makes it possible to isolate virtually any substation equipment from its power bus without physically removing the power bus, it eliminates the risk of equipment damage that's otherwise associated with testing.

Improved safety for maintenance personnel

The PCORE Test Terminal improves safety by minimizing boom and bucket truck crews' time.

Reduced downtime; maximized on-line time

Because the PCORE Test Terminal facilitates field dielectric testing compared with testing that requires removal of the power bus, it reduces equipment downtime and maximizes equipment on-line time delivering valuable electrical power.

Ease of use

The PCORE Test Terminal is easy to use. Bolts are captively affixed to the terminal so they won't become lost or be dropped during the testing procedure. And the terminal is designed so it can be easily attached to Doble and other test sets.

Reliable performance

The PCORE Test Terminal has a proven track record when it comes to reliable performance. In fact, over the last 35 years more than 15,000 PCORE Test Terminals have been installed worldwide in both new construction and in upgrade projects at existing substations.

Models, fittings available for multiple applications through 765 kV and 4000 amps

The PCORE Test Terminal may be used with any substation equipment which can benefit from periodic measurement of power factor or dissipation factor, including:

- Bushings on power transformers

- Bushings on SF6 gas circuit breakers (both live and dead tank versions)

- Bushings on air blast breakers

- Bushings on bulk oil circuit breakers

- Lightning arresters

- Current transformers

- Voltage transformers

Different terminal configurations are available for the top and bottom copper castings to tailor the test terminal for each application. Terminal configurations include spades with custom drillings, smooth and threaded studs, smooth and threaded female stud connectors, and custom drillings in the face of the top and bottom copper castings. Through system voltages of 230 kV, the PCORE Test Terminal is used without corona rings. At 345 kV, one corona ring is recommended. At 500 kV and 765 kV, two rings are recommended.

|