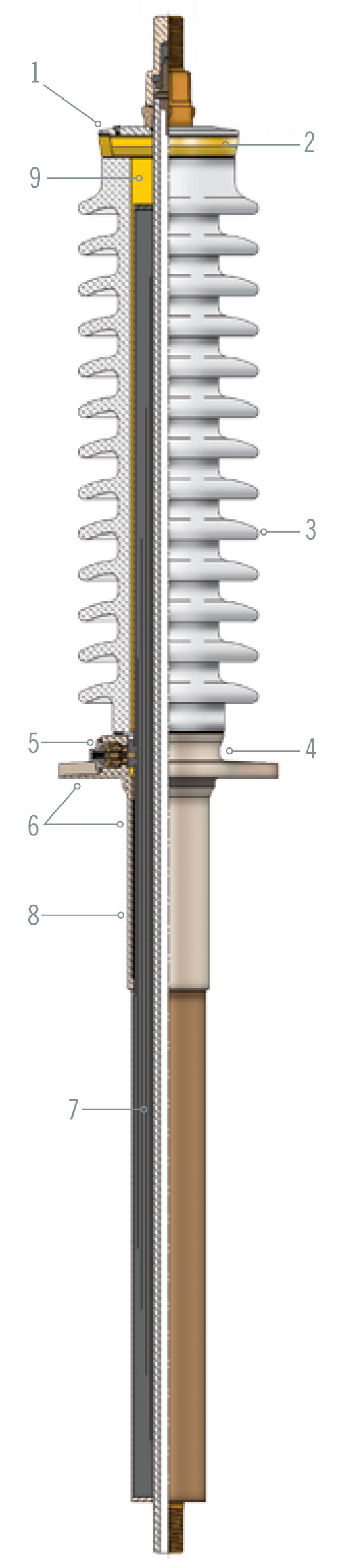

15kV-69kV PRC® Bushings (Paper-Resin-Capacitor)

PCORE capacitor bushings for transformer and oil circuit breaker applications are a proven design based on a capacitor core with aluminum foils and high dielectric paper impregnated with high dielectric epoxy resin. PCORE PRC bushings meet all ANSI/IEEE standards for outdoor apparatus bushings, where these standards apply, for voltage classes 15 kV through 69 kV. When an application results in overload above ANSI/IEEE standards, a bushing having a higher current rating is recommended. PCORE bushings are designed to carry the short term overloads specifed by ANSI/IEEE standards. PCORE PRC bushings for other applications (e.g., oil-to-oil, oil-to-gas, outdoor-to-indoor air, etc.) are available for various voltage classes and current ratings.

Design Features

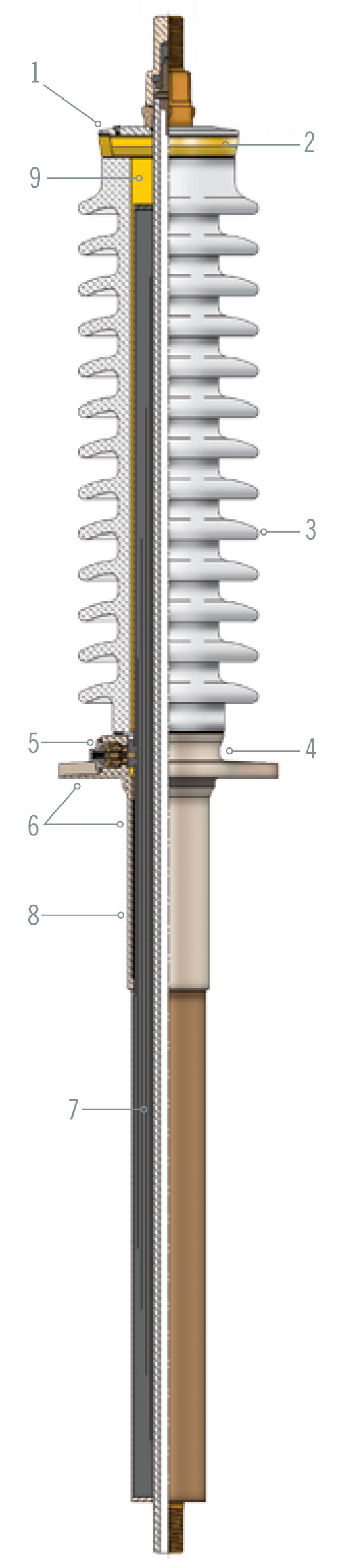

- Gaskets

Nitrile rubber, cork gaskets are designed to provide uniform, active loading to compensate for temperature variations and to assure oil-tight joints, reliable mechancial strength and extended life.

- Clear-View Oil Reservoir

The tinted glass oil reservoir filters damaging ultraviolet rays, preventing oil deterioration. The oil level and condition is clearly visible from any angle.

- Porcelain Housing

The outdoor porcelain housing has sturdy sheds to provide required leakage and strike distance and has ground surfaces on top and bottom ends for oil-tight gasket seals.

- Name Plate Data

The name plate affixed to the mounting flange identifies the bushing by catalog number, serial number and year of manufacture with electrical ratings and factory measurement data.

- Power Factor Test Tap

15 kV through 69 kV bushings have a power factor test tap. The test tap is connected to the ground layer of the capacitor core. An aluminum cap covers the insulated test tap assembly and grounds the tap to the flange when energized.

- Mounting Flange, Ground Sleeve Assembly

The mounting flange and ground sleeve assembly is made of aluminum and provides nonmagnetic, corrosion-resistant, high-strength service.

- Paper-Foil Capacitor Core

Conductive layers of aluminum foil with high dielectric paper are wound around the conductor and into the bushing core to produce uniformly valued capacitors in series. This capacitance grading distributes the voltage and the electrical field uniformly throughout the core. The core is vacuum-dried and impregnated with high dielectric epoxy-resin.

- Flange-Core Potting Compound

Once cured, the slightly resilient potting compound mechanically holds the flange-core assembly together and is an excellent shock absorber under dynamic cantilever loading.

- Dried, Degassed Oil

The internal space in the bushing above the flange and between the porcelain and core is filled with dried, degassed insulating oil.

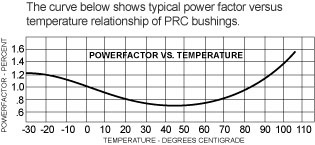

Unique Features of PCORE PRC Bushing Core

- Vacuum-impregnated with epoxy resin to provide a solid, void-free structure not subject to layer separation and, therefore, internal partial discharge as are resin-bonded cores.

- Totally-encapsulated with epoxy resin that is impervious to harmful conductive particle intrusion (i.e., water, carbon, etc.) unlike the surfaces of varnished paper cores, which crack due to aging.

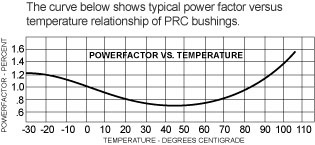

- Excellent dielectric system that has stable power factor, high mechanical strength, and superior thermal conductivity.

- Proven by over 40 years of outstanding field service.

|

|

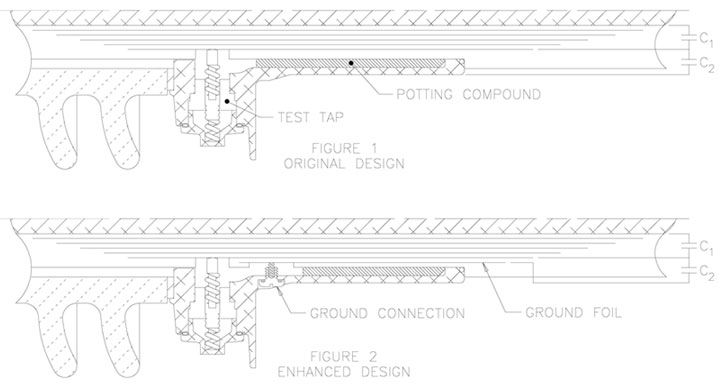

PCORE PRC Bushing Enhancement - C2

PCORE has enhanced the design of low-voltage PRC bushings.

An extra capacitance layer has been added to the outside of the core. This layer is permanently connected to the flange.

The layer was added to eliminate the effects of the potting compound when measuring the C2 capacitance and power factor.

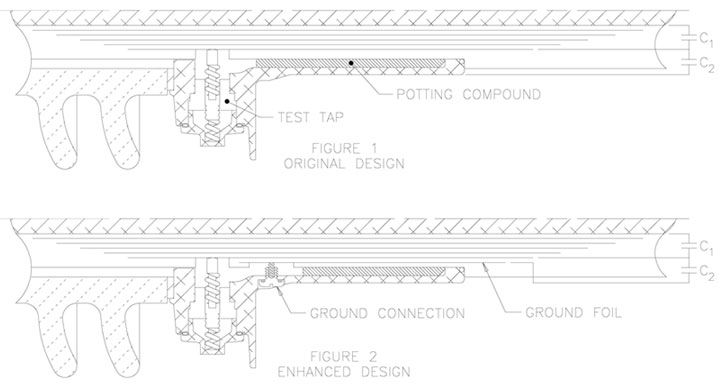

Before the change was made, the test tap was connected to the last foil in the core. (See Figure 1) The C2 capacitor was formed between the core and the aluminum flange casting. A significant part of the dielectric of this capacitor was the epoxy potting compound that was placed between the flange and the core. This compound was formulated for its mechanical properties and has a high power factor. Since the potting compound is shorted in service, the electrical properties of the material have NO EFFECT on the operation of the bushings. PCORE PRC bushings with the enhanced core designs have an extra foil which is permanently connected to the flange. The test tap is connected to a second foil at a slightly smaller diameter. (See Figure 2) The C2 capacitor on these bushings is formed between two foils within the resin impregnated core.

The result is a much lower C2 power factor, in the same range as the C1 power factor. Bushings with the enhanced design began shipping in May of 2000. They can be identified by the higher C2 capacitance values. Typically, they will be double or more than the capacitance of the original designs.

The original design cores and flanges are being shipped first, but it is possible to receive both original and enhanced designs of the same catalog number, on the same order.

The enhancement was made to address field questions regarding the C2 power factors on PCORE PRC bushings.

THE QUALITY AND PERFORMANCE OF THE TWO DESIGNS ARE IDENTICAL.

The C2 values are NOT listed on the nameplates of PRC bushings. If you have any questions, please contact the factory.

|

|